ODM/OEM

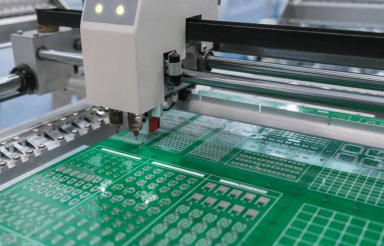

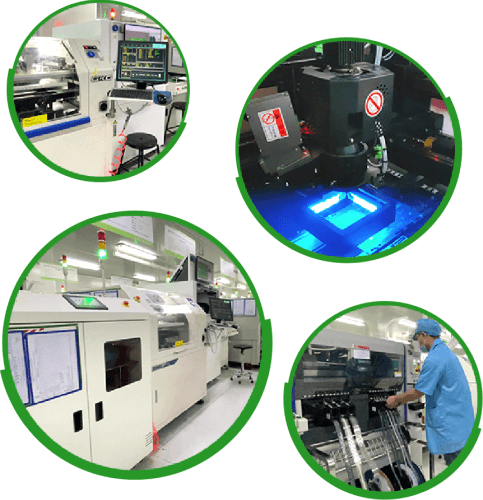

Support SMT/DIP process fully automatic high-precision SMT production line,

Brand new imported production equipment

Fill Information

Upload Zip、Rar or other compressed compatible file format. Max file size :50MB

Upload Zip、Rar or other compressed compatible file format. Max file size :50MB

Upload Zip、Rar or other compressed compatible file format. Max file size :50MB

What we can do for manufacturing

PCB Fabrication

Monkey provides the PCB Fabrication service, small batch production and big quantity production.

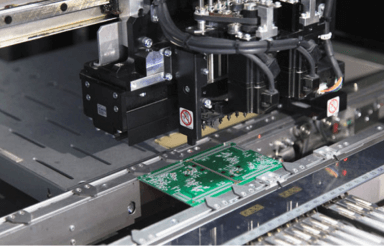

PCB Assembly

Monkey has the new SMT machines and e-flows soldering machines, which can meet various demands.

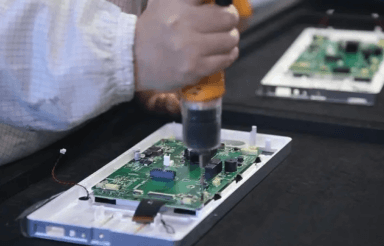

Box Build Assembly

Monkey provides the finish product assembly, testing and drop-shipping service.

What we can do for engineering

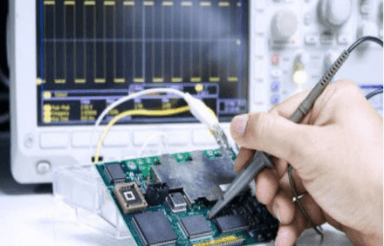

Testing Lab

Monkey has a big liability testing lab, which has more than 20 difference testing equipment. We can provide the professional testing service.

Hardware Design

Monkey has more than 40 experienced hardware engineers, including the analog/digital/RF engineers. We can the hardware design or JDM service to our customers.

Mechanical Design

Monkey has the mechanical engineers, which can provide the UI design or mechanical design to our customers.

Production Line

Production Line Specification

Automatic PCB unloader

The suction loading machine is with two PCB loading methods, which are particularly suitable for double-sided PCB

GKGG5 automatic printing machine

Printing speed: 2-30mm/s, automatic cleaning of steel mesh, repetition accuracy of 2.0cpk ± 10um

3D solder past detection machine

Resolution: 1.0um/pulse, detection accuracy: 10um

SMT machine: YAMAHA YSM20

Installation accuracy ± 0.035mm (± 0.025mm) Cpk ≥ 1.0 (3 δ) High speed mounting (HM) head 10 × 2. Installation capacity: 90000CPH per hour

SMT machine: YAMAHA YSM10

Installation accuracy: ± 0.035mm (± 0.025mm) Cpk ≥ 1.0 (3 δ) High speed mounting (HM) head 10, mounting capacity 46000CPH per hour

Reflow soldering: Nisso IPC-710A

10 heating zones, above and below each. Temperature control accuracy: ± 1 ℃

AOI Automatic Optical Detector

Inspection: missing parts, deviation, monument, side standing, flipped parts, extreme reversal, wrong parts, damage, tin connection, and faulty soldering

X-Ray Detector

Inspection: short circuits, open circuits, hot solder joints, dents, bends, etc. inside the circuit board

Storage board machine

Fully automatic storage board machine, distinguishing between good and bad products for storage

E-FLOW wave soldering

Dimension:4420(L)×1420(W)×1750(H)mm

Delivery Speed:0.5-1.8m/min

Base plate/component size :50-350mm(W)/上120mm

Spray movement: stepper motor

Flux device air pressure/capacity: 3-5 Bar/Approx.18L

Pre heater section 3 length: 1.8m

Tin furnace temperature: maximum 300 ° C

Automatic component cutting machine

Semi-automatic plate washer

Semi-automatic crimping machine